Project

What is ACROBA project ?

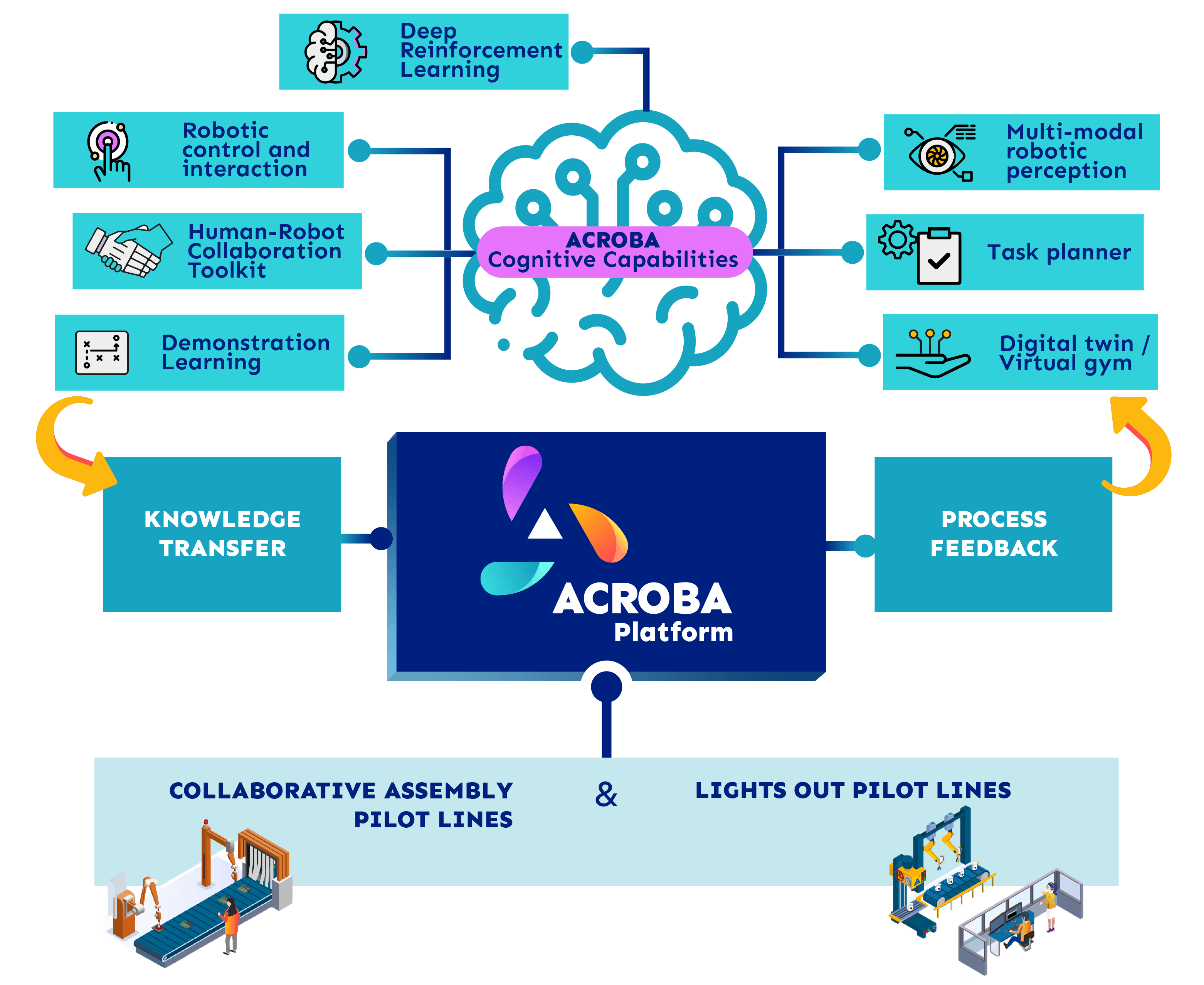

As modern industrial robotic systems become smarter and more flexible, they are rather tailored for specific, large scale applications, making its implementation too complex and costly for smaller operators. The ACROBA project aims to develop and demonstrate a novel concept of cognitive robotic platforms based on a modular approach able to be smoothly adapted to virtually any industrial scenario applying agile manufacturing principles. A novel ecosystem will be built as a result of this project, enabling the fast and economic deployment of advanced robotic solutions in agile manufacturing industrial lines, especially industrial SMEs

The novel industrial platform will take advantage of artificial intelligence and cognitive modules to meet personalisation requirements and enhance mass product customisation through advanced robotic systems capable of self-adapting to the different production needs. The platform will depart from the COPRA-AP reference architecture for the design of a novel generic module-based platform easily configurable and adaptable to virtually any manufacturing line. This platform will be provided with a decentralized ROS node-based structure to enhance its modularity.

ACROBA Platform will definitely serve as a cost-effective solution for a wide range of Industrial sectors, both inside the consortium as well as additional industrial sectors that will be addressed in the future.

ACROBA use cases

Autonomous robotic solution applied to:

Additive manufacturing for medical devices production: automation of manual process (STERIPACK)

Robotic solution collaborating with human applied to:

Electric components assembly for electric motors manufacturing: automation of most manual intensive tasks, in a flexible process adapted to various component and a wide range of products (ICPE)

Electronic elements assembly for electronic circuits production: automation of small and large customized series (IKOR)

ACROBA partners

With 17 entities from 9 countries, the ACROBA consortium covers the entire value chain concerning the robotic automation for agile production industrial companies.

SMEs are the major players in ACROBA project, with seven industrial SMES, four of them being the end users of the ACROBA Platform. In addition to the SME, ACROBA consortium also gather one Large Industry, five Research Centers, two Universities and two Clusters.

ACROBA other activities

In addition to the 5 demonstrators that will be developed during the project, the potential of the ACROBA platform as a cost-efficient cognitive robotic platform within agile production environments, will be demonstrated through two extra mechanism involving external actors:

Organisation of Hackathons

Hackathons runners will build a ‘proof of concept’ and an MVP for a specific predefined manufacturing problem identified as requiring an agile production solution. Each contest will result in several functional basic applications of a robotic system powered under ACROBA platform.

13 mini hackathons will be organised between mid-2022 and end of 2023 and all finalists will compete in the final master hackathon.

ACROBA On-Site Labs

ACROBA will support the uptake of novel intelligent technology by EU manufacturing SMEs willing to be agile in production by implementing Artificial Intelligence (AI) solutions into their production processes.

2 selected SMEs will be supported in the implementation of a robotics solution (powered under the ACROBA platform) to answer a current manufacturing problem they are facing on their Digital Transformation journey.