From some time now, robot teaching process was led by two techniques, always based on the displacement of the robot itself. On the one hand – taking into account light and collaborative robotics – the robot can be configured in a weightless mode that allows the operator to move its own joints and tool over different positions, while saving these points. This task is generally related to small robots, since moving large weights, and therefore large inertias, might become not only a dangerous task, but also technically complex. Another possibility, this time related to these larger robots, would be to move the robot along its path using a joystick or relative coordinates by recording these points

These methods present another disadvantage: making the programming movement in a considerable rigid and slow way. In this context, the Dummy Tool was born, as an innovative solution, particularly exploitable in industrial environments.

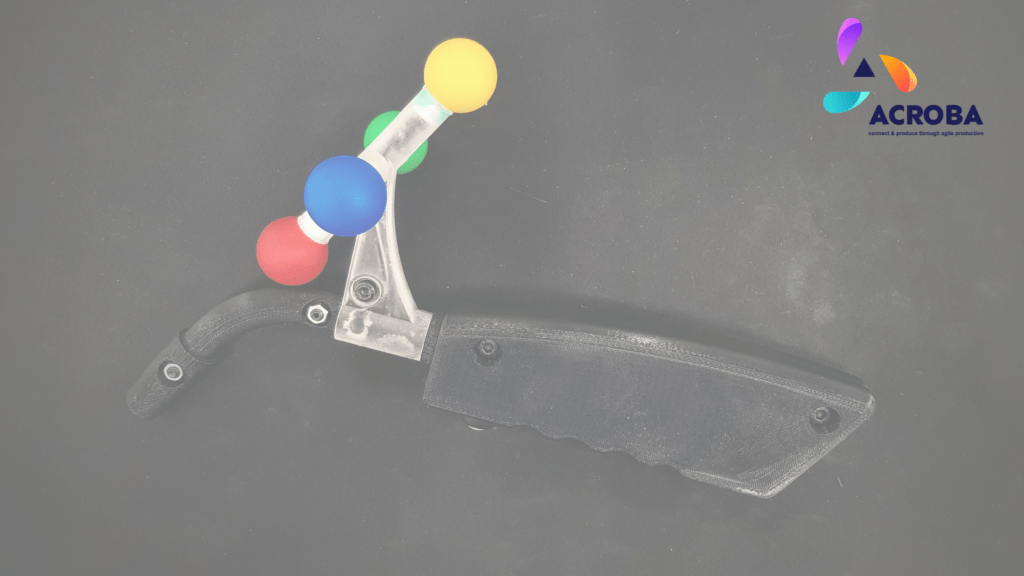

This system would represent a robot programming tool that makes it possible to capture trajectories in 6 degrees of freedom, effortlessly. The Dummy Tool is a lightweight, ergonomic device that gives the operator full freedom of movement. The operator just needs to walk along the routes he wants the robot to work on, flick a switch on the specific sections to record the required trajectory, and a system of cameras within the operational cell will capture the visual information and transform it into 6D coordinates. “6 degrees of freedom or 6 DoF” defines the motion of a rigid solid in a three-dimensional environment. Thus, the position recorded by the system will have for each point 3 coordinates defining its position and 3 angles defining its orientations.

The Dummy Tool’s system also has an artificial intelligence layer that refines these trajectories by adapting them to the geometries of the parts to be worked on (if CAD files are available) and by smoothing the trajectory and thereby erasing possible noises and disturbances induced by the operator. In this way, the result will be a smooth and geometrically consistent curve that fits the work surface.

Ultimately, Dummy Tool enables a faster, more ergonomic, and more accurate robot programming process than what has been achieved by previous systems. It will also be an adaptable process to the working cell in which the teaching process and robot work is taking place, making a subsequent adaptation of the trajectory to the specific cell own errors unnecessary.

Author : Iván Monzón, AITIIP