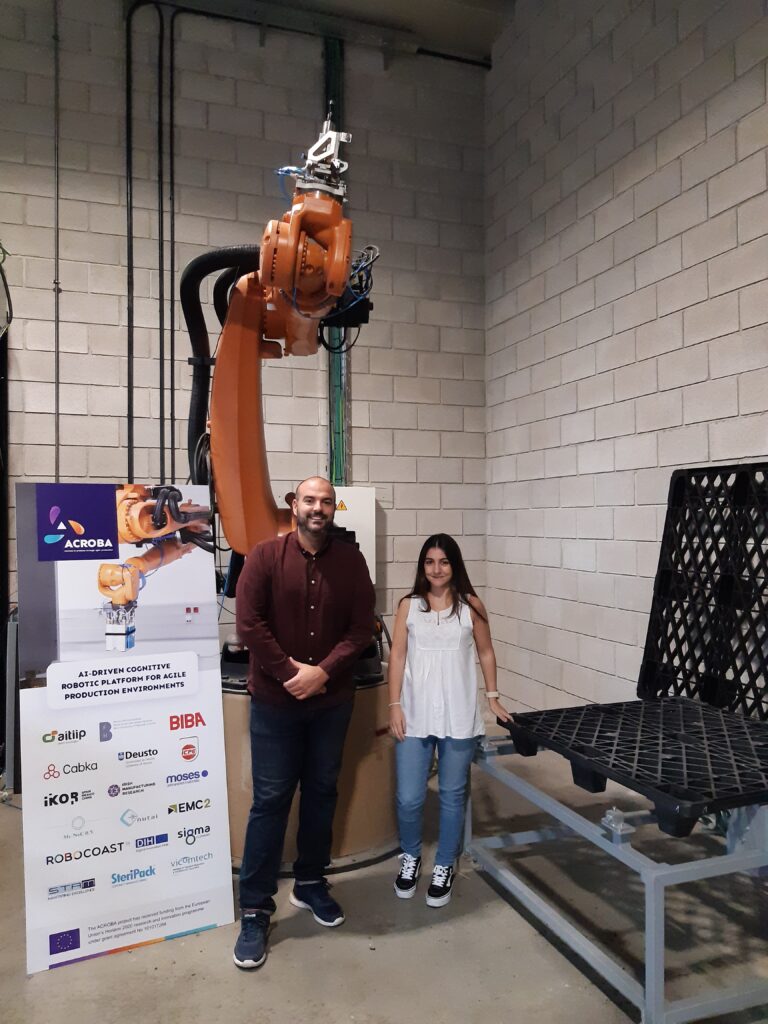

On 20-21 September 2022, the ACROBA project partners met in Valencia (Spain) for a general meeting hosted by CABKA. On this occasion, we spoke with Paula Llopis (Automation Team Lead) and Sergio Picazo (Programming Engineer), the faces of CABKA within the ACROBA consortium.

1. Please tell us in a few words about CABKA

Cabka is a multinational company specialized in high quality plastic pallets and large containers, having as strengths the development of innovative and reusable transports packaging solutions, the recycling of plastics and circularity.

2. What is the role of CABKA in the ACROBA project?

Cabka takes part in ACROBA project as a use case, applying all the development and knowledge acquired in a practical exercise. This system must be able to identify all possible defects in the pallets and drive the robots to remove the localized burrs. In addition to this, the purpose is also testing the system flexibility using a wide range of pallets.

3. Why did you decide to join the consortium?

The main reason for being part of this project is the actual need we have to develop a system that allow us to identify and correct defects in our products for the purpose of increasing quality and reducing scraps.

Joining the consortium gives us the opportunity to revalue the automation development in the company as well as the recognition of working together with prestigious companies and universities.

4. In what aspects do you expect that ACROBA will have the biggest impact?

Our goal is reply as much as possible the quality automated line for all the processes possible to improve the overall performance of our factories.

5. What are the 3 words that come to your mind when thinking about ACROBA?

Partnership, knowledge and technology.